Our philosophy is clear: don’t transit, transform!

We are pressing the Next button on the new world, an era in which buildings and infrastructure embody the future of the planet.

We’re not just keeping pace, we’re setting the pace.

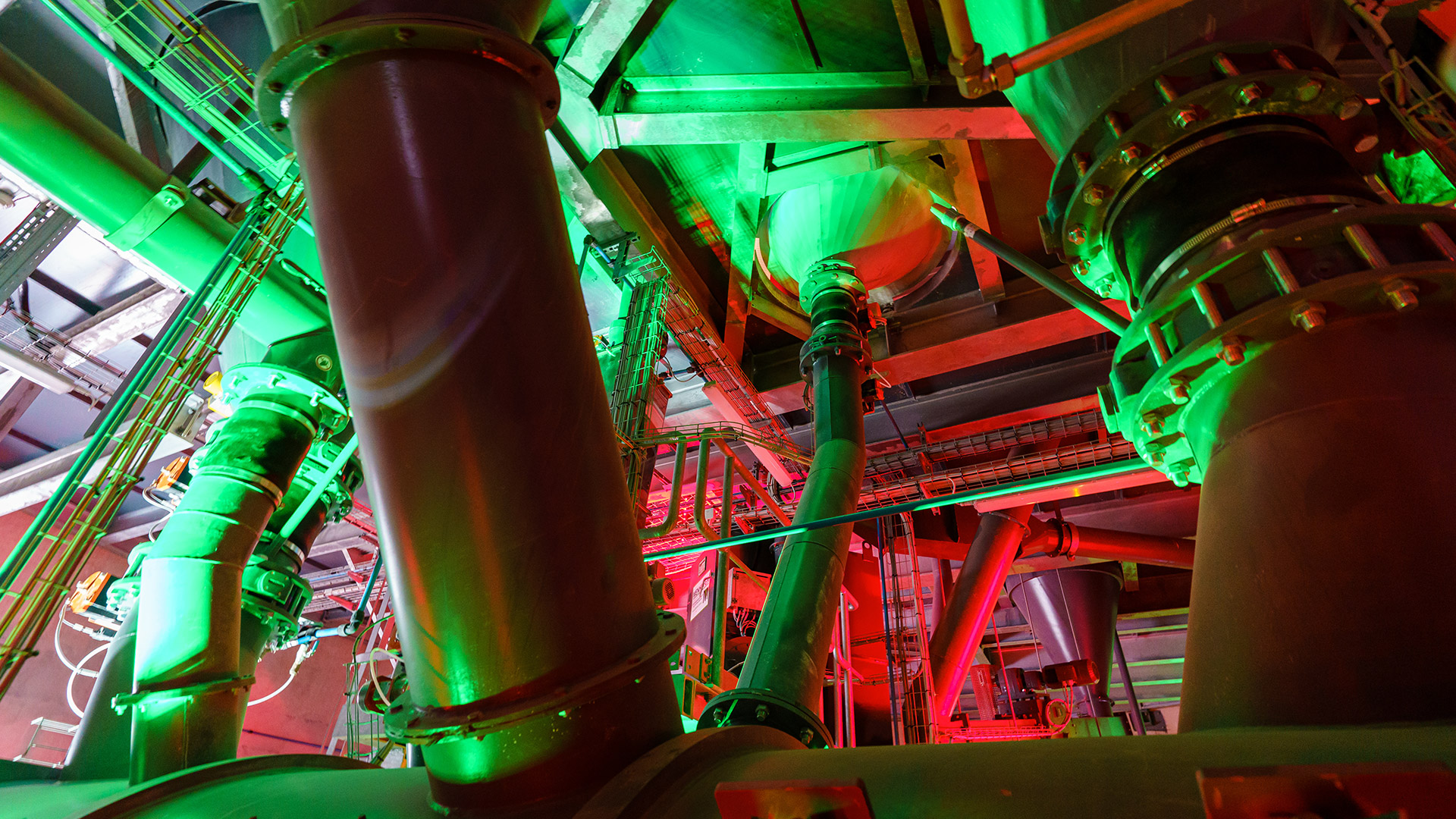

Our innovative cements mark a major technological breakthrough by drastically reducing carbon footprints compared with conventional cement. Our performance is not limited to respect for the environment. They set a new standard for the industry, while remaining in perfect harmony with existing manufacturing processes.

Our innovative cements mark a major technological breakthrough

In less than 10 years, the company has developed and marketed four ground-breaking solutions, setting a new standard for cement: a carbon-free 0% clinker cement. Bringing these unique cements to market required extensive R&D, certification, assessment and approval work to guarantee a level of performance at least equivalent to traditional cements.

Next, that’s the message Hoffmann Green spreads through our achievements. We don’t move on to the next stage, we are the next stage!

We believe in the power of a virtuous industrial approach that fully integrates environmental, social and societal impact. We are working to build a future based on the principles of sustainable development, placing the circular economy and the conservation of natural resources at the heart of our daily lives.